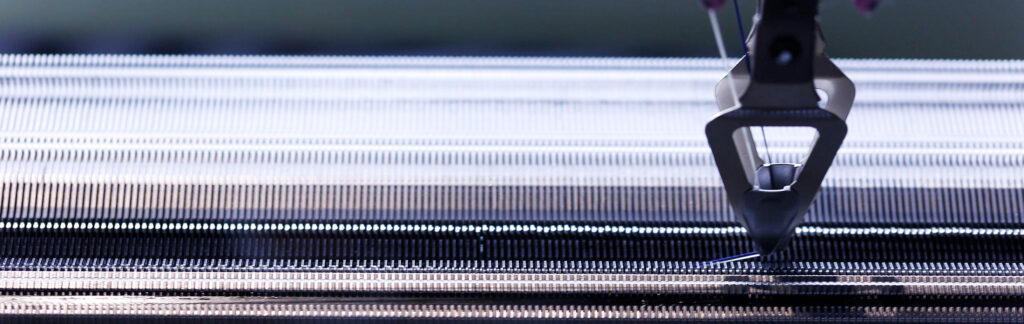

Cooperation between brands and bulkknitwear manufacturers

- The importance of manufacturers

Manufacturers are one of the cornerstones of the development of fashion brands. They are not only manufacturers, but also the direct embodiment of brand quality. Whether it is clothing, accessories, or other fashion products, the ability of manufacturers determines the quality of products, the possibility of design realization, the flexibility of production, and whether the brand can stand out in the fiercely competitive market. High-quality manufacturers can not only improve the competitiveness of brands, but also help brands reduce production costs and shorten delivery cycles to meet market demand.

- How the relationship between brands and manufacturers affects brand success

Whether a brand and manufacturer can succeed depends on whether the two parties can reach a high degree of tacit understanding and trust during the cooperation process. In the early stages of brand establishment, manufacturers often bear huge responsibilities to ensure that the raw material selection, production process and quality inspection of products are consistent with the brand’s positioning and market goals. If the manufacturer fails to meet the brand’s requirements, the brand’s reputation and market reputation will be affected.

A good cooperative relationship not only helps brands establish a high-quality image in the market, but also allows brands to face competition and challenges more calmly. In the case of unstable factors in the supply chain, such as changes in market demand, fluctuations in raw material prices, and logistics delays, close cooperation between manufacturers and brands can help both parties overcome difficulties together.

——————————————————————————————————————–

How to choose the right manufacturer

- Manufacturer screening criteria

When choosing a manufacturer, brands need to consider many factors to ensure that their capabilities and qualifications match the brand’s goals. The following are several key screening criteria:

Professional capabilities: Does the manufacturer have the technology and experience to produce the products required by the brand? Are there any successful cases of similar products? Can it adapt to the innovative design and special process requirements that the brand may propose?

Production scale and flexibility: Can the manufacturer’s production capacity meet the current and future growth needs of the brand? Can they provide flexible production arrangements based on market demand fluctuations?

Supply chain management: Does the manufacturer have a stable supply channel for raw materials? Can their supply chain management system support on-time delivery without causing a full-line stagnation due to a break in a certain link?

Qualifications and certifications: Does the manufacturer have industry-related qualifications and certifications, such as ISO quality certification, environmental protection certification, etc.? These qualifications not only guarantee the manufacturer’s production capacity, but also help brands meet the compliance requirements of specific markets.

Culture and value matching: Are the manufacturer’s corporate culture, social responsibility and brand values consistent? This is especially important for fashion brands that focus on sustainable development.

- Manufacturer’s strength assessment

When choosing a manufacturer, brands need to conduct on-site inspections and multi-angle assessments. Here are a few key steps:

Visit the factory: By visiting the factory on site, understand the manufacturer’s production equipment, workers’ technical level, factory management process, etc., and judge whether their production capacity meets the brand’s needs.

Review cases: By reviewing the brands and product cases that the manufacturer has cooperated with in the past, evaluate their design conversion capabilities, production stability and delivery records.

Third-party audit: For some larger-scale cooperation, a third-party quality inspection agency can be hired to conduct an independent audit of the manufacturer’s production capacity, quality control system and management level.

——————————————————————————————————————–

Establish an effective communication and trust mechanism

- Frequency and transparency of communication

Effective communication is the core of successful cooperation between brands and manufacturers. At all stages of cooperation, both parties should maintain a high degree of transparency and timely feedback. The frequency of communication should be set according to production progress and project requirements. For example, regular communication and follow-up should be carried out at key nodes such as the design proofing stage, before production starts, and before delivery.

Manufacturers’ transparency is reflected in their willingness to share production progress, possible production problems and solutions, while brands need to clearly express their requirements for product quality, delivery time and other details of cooperation.

- Understanding and respect for cultural differences

In a global supply chain, brands and manufacturers may be located in different countries and regions, and cultural differences are inevitable. This cultural difference is not only reflected in language communication, but may also affect working methods, time concepts, decision-making processes, etc. Therefore, brands need to respect the cultural background of manufacturers and establish clear communication rules and standards at the beginning of cooperation to avoid misunderstandings and cooperation barriers caused by cultural differences.

- How to build trust through communication

The basis of cooperation between brands and manufacturers is trust, and the establishment of trust requires time and communication. Brands can enhance the trust relationship between the two parties in the following ways:

Regular factory visits: Not only should factory audits be conducted at the beginning of cooperation, but factory visits should also be conducted regularly during the cooperation process to understand the production status and maintain face-to-face communication with manufacturers.

Regular feedback and improvement: After the product is delivered, the brand should provide product feedback to the manufacturer and discuss future improvement directions with them. This positive feedback mechanism not only helps to improve product quality, but also enhances the tacit understanding of cooperation between the two parties.

——————————————————————————————————————–

How brands ensure product quality

- Establishment of quality control process

Ensuring product quality is one of the core tasks in the cooperation between brands and manufacturers. Brands should jointly establish a complete set of quality control processes with manufacturers, from the procurement of raw materials, monitoring during the production process, to the testing of finished products, to ensure that each link can meet the brand’s high quality requirements.

- The quality control process can include the following aspects

Raw material testing: Ensure that each batch of raw materials can meet the brand’s quality standards.

Production process monitoring: Regularly check the production line to ensure that each link in the production process can be carried out in accordance with the standards.

Finished product inspection: After the product is completed, a comprehensive quality inspection is carried out, including appearance, size, function, etc., to ensure that the finished product meets the design requirements.

- How to deal with product quality problems

When there is a problem with product quality, the brand and the manufacturer should jointly explore solutions to ensure that the problem is solved quickly and reduce the impact on subsequent production. The following are several steps to deal with quality problems:

Problem confirmation: The brand should immediately feedback the problem found to the manufacturer and provide a detailed description and test results to ensure that both parties have a consistent understanding of the nature and severity of the problem.

Cause analysis: The manufacturer should conduct a comprehensive inspection of the production process to find out the root cause of the problem. Problems may come from multiple links such as raw materials, process control or production equipment. Finding the exact cause is the key to solving the problem.

Adjustment and improvement of the plan: According to the specific cause of the problem, the manufacturer should formulate corrective measures, such as adjusting the production process, changing suppliers, and improving quality inspection standards. The brand should participate in the discussion and ensure that the improvement measures meet the brand’s standards.

Division of responsibilities and remedial measures: If the problem seriously affects the brand’s product quality or market delivery, both parties need to clarify the responsibility. Generally, the manufacturer should be responsible for its quality errors, including rework, replenishment, compensation, etc.

- Quality assurance agreement and contract

In cooperation with manufacturers, the brand should clarify the requirements and responsibilities of both parties for quality through a formal contract or agreement. The content of the contract may include but is not limited to the following points:

Quality standards: Clearly list the specific quality requirements of the product, including size, color, material composition, process details, etc.

Quality inspection process: Specify the quality inspection frequency, sampling ratio, inspection method, etc. in the production process to ensure that the quality of the product meets the brand requirements.

Breach of contract handling: The contract should clearly stipulate the responsibilities and remedial measures that the manufacturer needs to bear once a quality problem occurs, such as how to handle returns and how to compensate for the brand’s losses.

——————————————————————————————————————–

Negotiation strategies for price and cost

- How to negotiate price and cost

When working with manufacturers, price and cost negotiation is a key link. Brands need to ensure the control of production costs while ensuring product quality. Here are several effective negotiation strategies

Understand the market situation: Before negotiating with manufacturers, brands need to have a certain understanding of market prices, including the cost of raw materials, workers’ wages, logistics costs, etc. This can avoid over-quotations caused by information asymmetry.

Batch production advantages: If the brand has large-scale order requirements, manufacturers usually offer more favorable prices. When negotiating, brands can use long-term cooperation and batch production as bargaining chips to ask for a reduction in the production cost of a single product.

Comprehensive cost assessment: When negotiating, not only should the manufacturer’s quotation be considered, but also other costs such as transportation, tariffs, inventory management, etc. should be comprehensively evaluated. Overall cost control is more important than a simple production quotation.

Comparison of multiple suppliers: Brands can compare quotations from multiple suppliers and choose the most cost-effective partner. This not only helps brands get more competitive prices, but also increases bargaining chips for negotiations.

- How to balance quality and cost

In price negotiations, brands need to avoid excessively lowering costs, which causes manufacturers to sacrifice product quality to maintain profits. Therefore, brand decision makers should focus on how to reasonably control costs while ensuring high quality.

Flexibility in material selection: On the premise of meeting brand design and quality requirements, brands can discuss flexibility in material selection with manufacturers and choose more cost-effective raw materials instead of blindly pursuing the highest specifications of materials.

Optimization of production processes: Manufacturers can reduce costs by optimizing production processes and improving production efficiency. Brands can work with manufacturers to study how to simplify production processes without affecting quality.

Long-term cooperation and cost benefits: Establishing a long-term cooperative relationship with manufacturers often results in more favorable cost quotations. Brands can exchange manufacturers’ price discounts by promising long-term orders or increasing production scale.

- Pricing mechanism for long-term cooperation

In long-term cooperation, brands and manufacturers should establish a flexible pricing mechanism that can cope with market price fluctuations. For example, the rise or fall of raw material prices may have an impact on production costs. Brands and manufacturers can stipulate price adjustment mechanisms in the contract to ensure that both parties can maintain a reasonable profit margin in the market changes.

——————————————————————————————————————–

Legal protection and risk management in cooperation

- Importance of contract

Regardless of the scale of cooperation, brands and manufacturers should sign a formal contract to clarify the rights and obligations of both parties. The contract is the legal guarantee of the cooperative relationship. Once a dispute occurs, the contract will serve as the basis for both parties to resolve the problem. The following are the key contents that should be included in the contract

Product specifications and requirements: The contract should list in detail the specific requirements of the product’s design, specifications, raw materials, packaging, etc. to prevent production deviations caused by differences in understanding.

Delivery time and delay liability: clarify the delivery date and delivery method, and stipulate the liability and fines that the manufacturer should bear in case of delay.

Payment terms: stipulate the payment method, payment time and compensation terms in case of breach of contract to ensure that the brand can pay on time and the manufacturer can deliver on time.

Intellectual property protection: For brands with more complex or innovative designs, the contract should clearly state intellectual property protection clauses to prevent manufacturers from copying or leaking the brand’s design without authorization.

Dispute resolution mechanism: The contract should include dispute resolution clauses, such as arbitration clauses or the selection of specific court jurisdictions, to ensure that disputes can be quickly resolved once they occur.

- Avoid risks in the supply chain

The supply chain of the fashion industry is relatively complex. In the cooperation between brands and manufacturers, there may be many uncontrollable risks, such as shortages of raw materials, logistics delays, changes in market demand, etc. Brands can avoid these risks in the following ways

Diversified supply chain: Avoid concentrating all production needs on one manufacturer or region, and reduce risks by working with multiple suppliers. Even if a manufacturer encounters a problem, the brand can quickly find an alternative supplier.

Establish a risk warning mechanism: Brands can require manufacturers to provide regular production progress reports to detect potential production problems in a timely manner. Once a risk is discovered, the emergency plan can be immediately activated to avoid affecting product delivery.

Supply chain insurance: In order to further reduce the economic losses caused by uncontrollable factors, brands can purchase supply chain insurance to cover possible production delays, logistics problems, natural disasters and other risks.

- Dealing with emergencies

In the face of unforeseen emergencies, brands need to have a complete set of emergency plans to ensure that they can respond quickly and minimize losses when the supply chain is interrupted. The following are several effective response strategies

Maintaining cooperative relationships with multiple suppliers: Working with multiple manufacturers and raw material suppliers can help brands quickly find alternatives when the supply chain is interrupted. For example, if a natural disaster occurs in a certain area or logistics are blocked, the brand can immediately turn to suppliers in other regions to ensure that production is not interrupted.

Flexible production plan: When formulating production plans, brands should take into account the possibility of emergencies and maintain a certain degree of production flexibility. For example, in some orders, unforeseen delays can be dealt with by adjusting the production sequence, extending the delivery time, or even modifying the product design.

Supply chain data tracking: For the progress of brand design, manufacturers can be required to provide videos or relevant databases every period of time. Ensure that the design can be carried out according to the specified time.

Develop emergency contract clauses: When signing a contract with a manufacturer, the brand can include clauses on emergencies, such as “force majeure” clauses, stipulating the responsibilities and obligations of both parties in the event of natural disasters, wars, epidemics, etc.

Through these emergency strategies, brands can respond more calmly in emergencies, ensuring the stability of the supply chain and the continued competitiveness of the brand in the market.

——————————————————————————————————————–

Maintaining a long-term cooperative relationship with BulkKnitwear

Establishing a long-term cooperative relationship with manufacturers can not only improve production stability and product quality, but also bring many other advantages to the brand

Improvement of production efficiency: Long-term cooperation can allow manufacturers to better understand the needs and standards of the brand, reduce communication costs, optimize production processes, and thus improve production efficiency.

Quality consistency: Through long-term cooperation, manufacturers can better grasp the quality requirements of the brand, continuously optimize the production process, and ensure that each batch of products can maintain consistent quality.

Cost control: In the long-term cooperation with the brand, manufacturers can reduce costs through economies of scale, process optimization and supply chain integration, and the brand can also obtain more favorable production prices.

Technological innovation and support: Through long-term cooperation with manufacturers, brands can obtain innovative support from manufacturers in production technology and processes. Manufacturers often upgrade technology according to the needs of the brand to enhance the competitiveness of their products.

- Growing together with BulkKnitwear

In order to maintain a long-term cooperative relationship, brand decision makers should focus on growing together with manufacturers for mutual benefit. Here are some strategies to promote partnerships

Joint development plans: Brands can work with manufacturers to develop long-term development plans, including technology upgrades, capacity expansion, new product development, etc. Through joint development, manufacturers can get more production opportunities, while brands can get more high-quality production resources.

Transparency in partnerships: In long-term cooperation, brands should maintain a high degree of transparency with manufacturers, share information such as order forecasts, market demand and product planning, and help manufacturers better plan production resources. This transparent cooperation model can enhance trust between the two parties and reduce misunderstandings and conflicts.

Order priority: For manufacturers with long-term cooperation, brands can give priority production opportunities for future orders, thereby ensuring that their production plans are more stable.

Jointly develop new products: Brands can work with manufacturers to jointly develop new products or new technologies. This can not only help manufacturers improve their technical capabilities, but also enhance the brand’s market competitiveness.